A demonstration section of porous pavement in front of the LGA offices in Lake George show the effective performance of the material during the winter months; ice and snow does not build up on the surface of the material to the degree that it does on the traditional gravel surface surrounding the porous section.

A demonstration section of porous pavement in front of the LGA offices in Lake George show the effective performance of the material during the winter months; ice and snow does not build up on the surface of the material to the degree that it does on the traditional gravel surface surrounding the porous section.

Beach Road at the south end of Lake George will be re-built this spring with an unconventional pavement: porous asphalt. Upon completion, Beach Road will become the first heavily traveled roadway in New York State (and one of the only roads in the Northeast) to be paved with porous asphalt.

“This is one of the most important lake saving projects ever for Lake George,” said Walt Lender, LGA executive director, “and a first of its kind for New York State,” he said. “The LGA recognizes both Warren County Superintendent of Public Works Jeff Tennyson, the state Department of Transportation, and the Federal Highway Administration for taking the bold steps to move forward on this revolutionary project, one we believe will get national recognition, and will set a precedent for many like it to follow in other lakeside communities,” said Lender.

The engineering firm of Barton & Loguidice (B&L) is designing the project, which has been funded with state, federal and county monies. Construction will begin in May of this year with completion in the fall of 2013. The porous pavement will be installed between Canada Street and Fort George Road.

Current plans for the timing of the project are:

– Late Feb 2012: Warren County releasing bid packages to contractors

– Early May 2012: Contract awarded

– June 2012: Groundbreaking for the project

– July 2012 – Nov. 2013: Construction

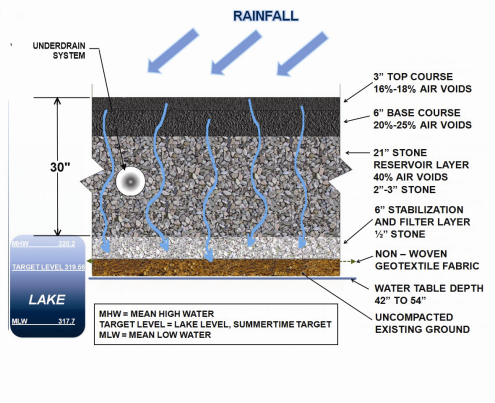

Porous asphalt is mixed with stone that is coarser than that used in conventional pavement. Without sand and finer particles in the mix, air takes up the spaces in the porous asphalt once occupied by the smaller particles. These air, or void, spaces account for approximately 15-20% of the volume in porous asphalt pavements compared to approximately 2% for conventional non-porous pavement mixes. During a storm event, water passes through the air voids in the asphalt down to an underlying stone reservoir layer comprised of clean, washed, angular shaped stone, uniformly sized in the 2” to 3” range. Stormwater is temporarily stored in this 12- to-30-inch-thick reservoir layer as it is absorbed into the underlying soils below. It is in the asphalt, stone, and underlying soil layers that trap and break down the contaminants carried by the water.

Within the past 10 years new polymers and additive fibers have been developed that are much more effective in binding the larger stone in the asphalt mix. These polymers and additive fibers have improved the durability of permeable asphalt in recent years.

One of the greatest benefits of porous pavement is the need for less road salt in the winter. Reductions in salt usage on porous pavement have shown to be 50% or greater in many communities with the greatest reductions in use coming between storms since the need for salt to control black ice is significantly reduced.

Salts (or chlorides) are a soluble (dissolved in water) contaminant and cannot be removed by the porous pavement structure, ponds, wetlands, or vegetated swales. It is by reduction of their use that will be the benefit to the lake. Other pollutants such as zinc, lead, copper, chemical oxygen demand, cadmium, and total phosphorus have shown removal rates of 40% to 95% in porous asphalt applications (source: NYSDEC).

(Click on images to see full scale.)